Types of Dutch Ovens

Types of Dutch Ovens

Sobald die Ölfläche gleichmäßig verteilt ist, kommt die Pfanne in den vorgeheizten Ofen. Man empfiehlt, den Ofen auf eine Temperatur von etwa 180–200 Grad Celsius einzustellen. Legen Sie die Pfanne kopfüber auf das obere Regal des Ofens und stellen Sie ein Backblech darunter, um eventuell tropfendes Öl aufzufangen. Die Pfanne sollte für mindestens eine Stunde im Ofen bleiben. Dieser Prozess ermöglicht es dem Öl, in das Gusseisen einzudringen und eine schützende Schicht zu bilden.

ကိုယ်တိုင် ဖရိတာဦးစီးထုကြီးကို စီမံထားခြင်းဖြင့် အစားအစာအဟောင်းကျူးလွန်မှုကို အောင်မြင်စွာ ပေးစုပြီး ခံစားခြင်းကို အထူးထား၍ လမ်းမှန်ကဖောက်တောဟု အဓိပ္ပါယ်ထားထားသည်။

Whether you are a novice cook or a seasoned chef, this grill is incredibly user-friendly. It is constructed from high-quality materials that ensure even heat distribution, preventing hot spots that can lead to uneven cooking. This means that your food cooks to perfection every time, allowing you to impress your family and friends with beautifully grilled dishes. Moreover, its non-stick surface makes for easy cooking and even easier cleanup. A simple wipe down with a damp cloth is all it takes to maintain your grill, giving you more time to enjoy your meals without the hassle of extensive post-cooking chores.

ग्याँस ग्रिलका लागि कास्ट आइरन ग्रिडल टप

1. Preheat Properly While many recipes require you to preheat your oven, it's essential to allow the Dutch oven itself to reach the right temperature as well—this ensures even cooking from the start.

Hydroxyethyl cellulose (HEC) is a nonionic, water-soluble polymer derived from cellulose, a natural polymer obtained from plant cell walls. HEC is widely used in various industries, including pharmaceuticals, food, and cosmetics, due to its unique properties, particularly its solubility in water. This article will explore the solubility of hydroxyethyl cellulose in water and its implications for various applications.

Properties of HPMC

Hydroxypropyl methyl cellulose is a highly versatile compound with significant applications across various industries. Its unique properties make it a valuable ingredient in pharmaceuticals, food, cosmetics, and construction materials. Understanding the manufacturing process and the importance of selecting a reputable manufacturer is key to ensuring the quality and efficacy of HPMC in any formulation. Whether you are a pharmaceutical company looking for excipients or a food manufacturer seeking texture improvement, HPMC undoubtedly plays a vital role in enhancing product performance and consumer satisfaction.

In conclusion, Hydroxypropyl Methylcellulose (HPMC) plays a vital role in multiple industries due to its remarkable properties. Its effectiveness as a thickening agent, binding agent, and film former, combined with its non-toxic and biodegradable nature, makes it an essential ingredient in pharmaceuticals, food products, cosmetics, and construction materials. As innovation continues, the applications of HPMC are likely to expand, reinforcing its importance in contributing to functional formulations that meet modern consumer demands. The future of HPMC undoubtedly holds promise as it caters to the evolving needs of industries while maintaining an environmentally conscious approach.

What is HPMC?

Understanding Hypromellose (HPMC) Applications and Benefits

In the pharmaceutical industry, MHEC serves multiple purposes. It acts as a suspending agent for liquid formulations, improving the stability of active ingredients and ensuring even distribution throughout the solution. Moreover, MHEC is used as a binder in tablet formulations, enhancing the mechanical strength and ensuring that tablets can withstand handling and transportation. Its film-forming capabilities are also utilized in coating applications, providing controlled release properties for various medications.

Conclusion

Applications in Pharmaceuticals

In conclusion, hypromellose (HPMC) is a multifunctional polymer that plays a crucial role in various industries, including pharmaceuticals, food, and cosmetics. Its favorable properties, such as solubility, safety, and versatility, make it an essential ingredient in countless applications. As research and innovations continue, it is likely that HPMC will find even more uses, further solidifying its importance in modern formulations.

Understanding HPMC Types An Overview

In personal care products, such as shampoos, conditioners, and lotions, MHEC is utilized for its thickening and emulsifying properties. It improves the stability of formulations, enhancing the sensory experience for consumers. Moreover, MHEC is used in various cosmetic applications, providing film-forming properties that aid in the longevity of products on the skin or hair.

Conclusion

Redispersible latex powder is a dry polymer that can be re-dispersed in water to form a stable emulsion. It is produced by spray-drying aqueous polymer dispersions, which encapsulates the polymer particles in a dry form. When mixed with water, these particles rehydrate and regain their original properties. This unique capability makes redispersible latex powder an ideal additive for dry-mixed mortars, tile adhesives, and other building materials.

In summary, the manufacturing process of hydroxyethyl cellulose involves the careful selection of raw materials, chemical modification through hydroxyethylation, purification, and rigorous quality control. The versatility and functionality of HEC make it a valuable ingredient across various industries, and the precision in its production is essential for its performance in end applications. The continuous development of more efficient production methods and sustainability practices remains a focus in the hydroxyethyl cellulose manufacturing landscape.

Key Applications of VAE Redispersible Powder

In conclusion, Methyl Hydroxyethyl Cellulose is a critical material with a wide range of applications across various industries. Manufacturers play an essential role in producing high-quality MHEC that meets the specific needs of each sector. As industries evolve and seek innovative solutions, the demand for MHEC and its manufacturers will undoubtedly continue to rise, making them integral to future advancements in technology and product development.

Conclusion

Chinese companies have increasingly invested in research and development to improve the quality and performance of HPMC, exploring new grades and formulations to meet specific industry needs. The availability of various viscosity grades and substitution patterns allows formulators to tailor HPMC for specific applications, enhancing its appeal across multiple sectors.

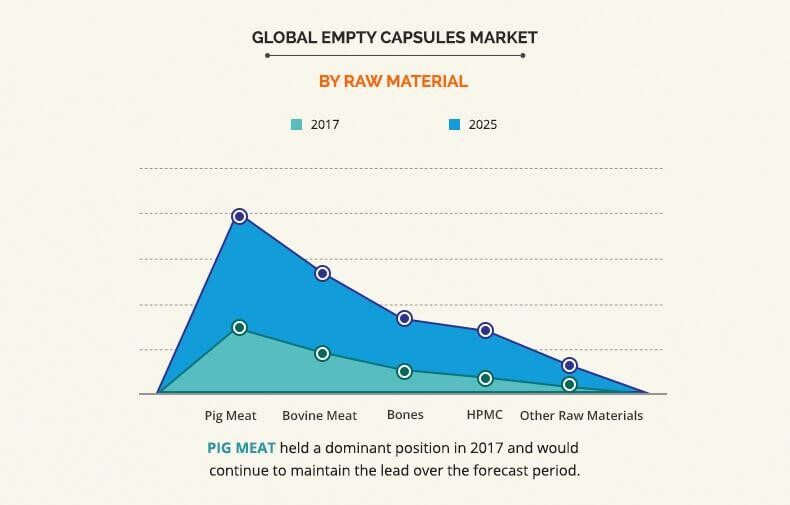

The demand for gelatin capsules/HPMC capsules for oral consumption has risen considerably due to its universal use without any fillers. In 2014, around 10%-15% of the USA’s supplements and medications were launched in capsule form, compared to just 5% in 2007.

- Pharmaceuticals In the pharmaceutical industry, HPMC is frequently used as a binder in tablets, a coating agent for controlled-release formulations, and a stabilizer in suspensions.

1. Pharmaceutical Applications

As the construction industry continues to evolve, the use of additives like HPMC in gypsum plaster represents a significant advancement in material technology. The benefits of improved workability, water retention, reduced shrinkage, enhanced adhesion, and customization make HPMC a valuable component in creating high-quality gypsum-based products. Its application not only streamlines the construction process but also enhances the durability and aesthetic appeal of building finishes. As such, HPMC will likely continue to play a crucial role in the future of construction materials.

1

2. Coatings RDP is also widely used in the coatings industry. It improves the performance of paints and coatings by increasing their flexibility and durability. The addition of RDP contributes to better film formation and enhances the resistance to weathering and UV exposure.

HPMC is generally soluble in hot or cold water, forming a clear and viscous solution

. However, its solubility can be affected by several factors, includingHEC appears as a white or off-white powder that is odorless and tasteless. Upon dissolution in water, it forms a viscous colloidal solution. The concentration of HEC in the solution can significantly affect its viscosity. Typically, higher concentrations lead to greater viscosity. A striking characteristic of HEC is its pseudoplastic behavior, where its viscosity decreases under shear stress, making it easier to process in applications where it is subjected to mechanical forces.

Applications of Redispersible Latex Powders

The applications of High-Performance Computing are vast and diverse, impacting numerous fields and driving innovation. Its ability to handle large datasets and complex computations is reshaping how research is conducted, products are designed, and decisions are made across industries. As technology continues to advance, the integration of HPC into everyday processes is expected to deepen, further enhancing our capacity to solve intricate problems and address global challenges. The future of HPC looks promising, presenting opportunities for new discoveries and advancements that will continue to transform our world.

When selecting a HPMC supplier in China, several factors should be considered to ensure a successful partnership

Hydroxypropyl Methylcellulose (HPMC) is a semi-synthetic polymer derived from cellulose, commonly used in the food, pharmaceutical, and cosmetic industries. It is primarily valued for its thickening, emulsifying, and film-forming properties. This article aims to explore the safety profile of HPMC, its applications, and regulatory perspectives.

In repair mortars, HPMC enhances the compatibility with existing materials and provides necessary flexural strength, making the repairs durable and less prone to failure. Moreover, as sustainable building practices become increasingly important, the ability of HPMC to improve the performance of eco-friendly binders will contribute to its growing popularity.